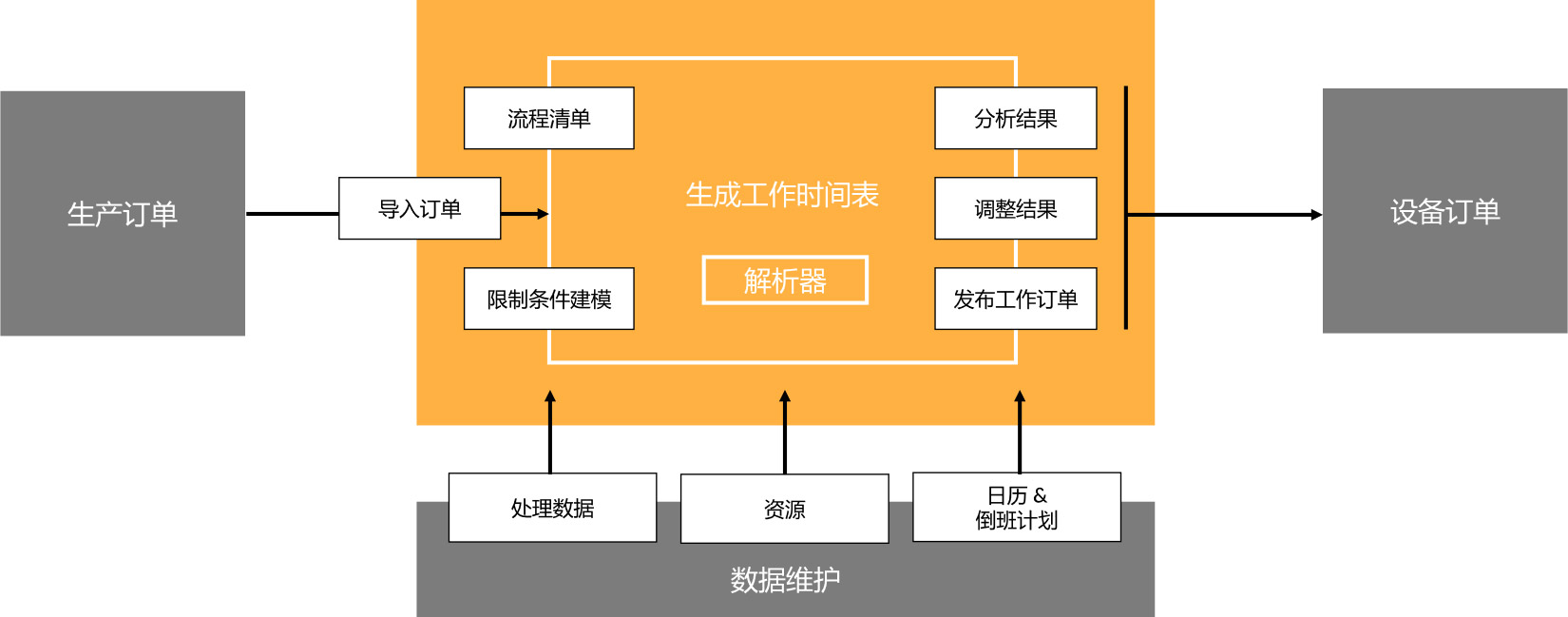

APS - 精细化排程

flexis 精细化排程优化了生产计划,落实了需求、资源和产能的透明度。这就给生产计划员提供精确的信息给客户成为可能。标准化得软件与MES和ERP的接口,无需安装特定软件即可使用,并可在云端部署。 在企业内的简单的、可扩展的、快速实施,可以立竿见影地即时对流程进行全透明的评估。

结果

降低成本, 通过极限化设备的设置和生产闲置,以及改进的生产过程。

效应

源于复杂性汽车行业的专业、高用户体验的标准化软件对中型企业进行了定制。任何x讯息可以通过MES/BDE接口或手动输入并集成到系统中。

详细描述

Flexis 精细化排程将计划值和实际反馈进行比较,以便进行有依据的重新排程。日程变更可以通过拖拽的方式进行调整,从而减少了繁琐手工操作的工作量(如使用Excel表格)。该程序在目标冲突的情况下提供决策辅助,并对工作内容、机器占用率、加工时间、人员和零件需求以及资源利用率进行概述。通过查看假设场景,提高了客户的沟通效率。

增值

- 数字孪生检验,以创建不同的场景

- 给销售和客户提供精准资讯

- 优化工艺流程,从而最大限度地减少设置耗费和闲置时间

- 提高生产计划和物流的效率

- 提高生产力

- 重要信息均结构化存档

- 通过云端部署,无需硬件投资和软件维护

flexis 解决方案一览

实情

提高设备利用率

直至20到

40%

缩短设备设置时间

直至15到

40%

通过特殊措施的节省成本

直至20到

40%