SCM - 多维度监控

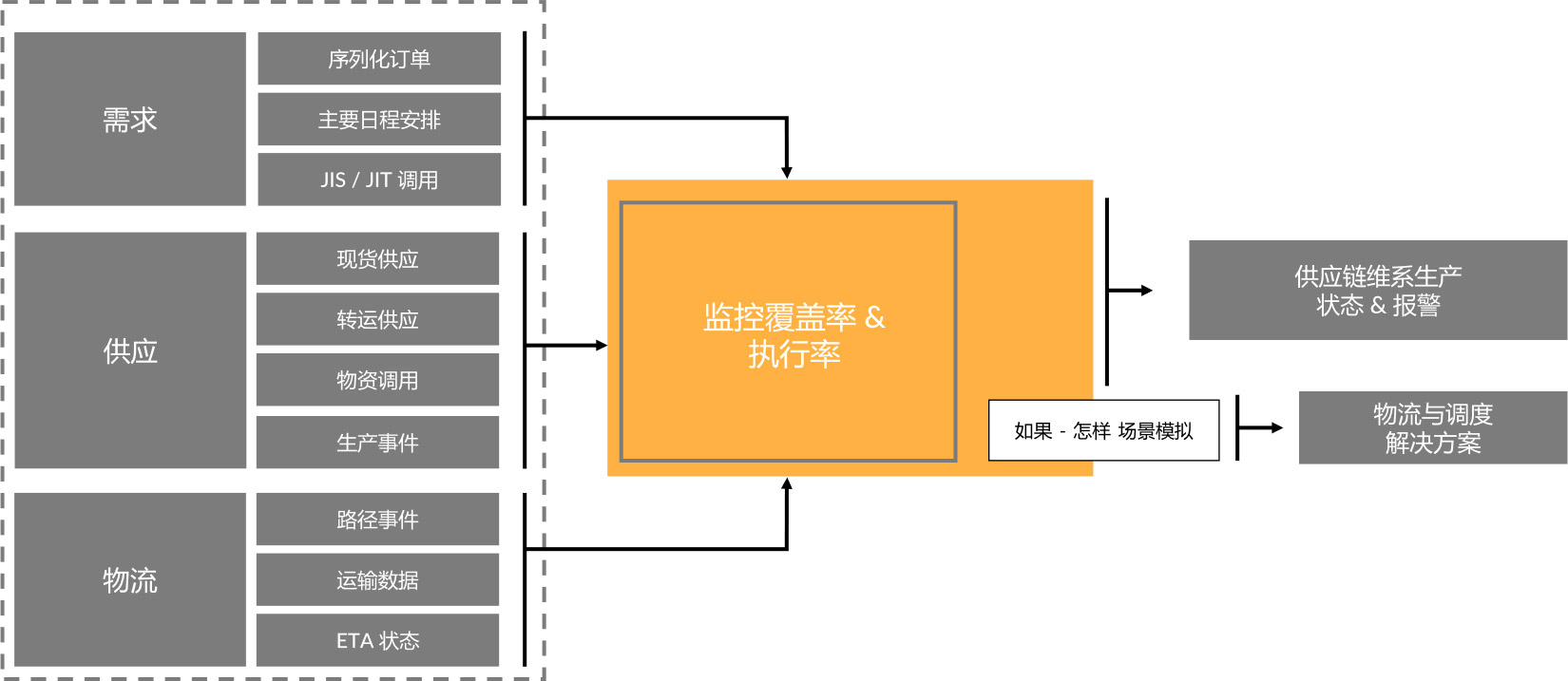

flexis多维度监控可实现运输、交付和生产状况的可视化,并提供有关瓶颈、范围和库存可靠的透明度。这款SCM解决方案可以在问题变得严重之前,客观、前瞻性地得到识别,甚至可以链接不同的层级架构。该方案还包括偏差管理,并将所有信息和数据实时传输到公司所有相关部门。

结果

该方案在保证供货能力的同时还能减少库存。生产力得到有效提升。

效应

该软件具有实时性,能对供应链在发生变化时做出自及时和适当的反应。

详细描述

通过 flexis 多维度监控解决方案,可以在全球环境下监控业务过程,为负责规划的人员提供生产和供应链的透明度。该软件可以识别和报告在冗长的供应链的关键节点。它为整个计划期间的生产过程和供应链过程创造了全面的透明度。通过预警功能,可以及早发现供应风险或瓶颈情况,并通过这种主动覆盖的状态,积极启动即时措施。

该软件系统可以监控长短期的供应链的零部件供应,甚至可以识别计划的顺序,并将库存和运输与生产进行比较。定义了造成瓶颈情况的部分。该程序提供了计划生产的安全库存概览,并确定了受零件瓶颈影响的订单。

flexis多维度监控为计划员创造了车间透明度,并清晰地显示订单状态。此SCM系统筛选,评估并自动确定计划的替代方案的优先级。

增值

- 基于实情的决策:"涡轮化透明"

- 知识的关联:对生产、储存和运输的整体看法

- 决策的安全基础:可控制而不是被动的作用

- 预警有风险的瓶颈:报警功能提供相关信息

- 清晰地展示风险部件或相关订单 Übersichtliche Darstellung von kritischen Teilen oder kritischen Aufträgen

flexis 解决方案一览

实情

减少安全库存

从 30 至

50%

生产效率提升,减少计划工作

大约 40 至

50%

通过避免特殊运输节约成本

从 20 至

50%