SCM - 运输计划与调度

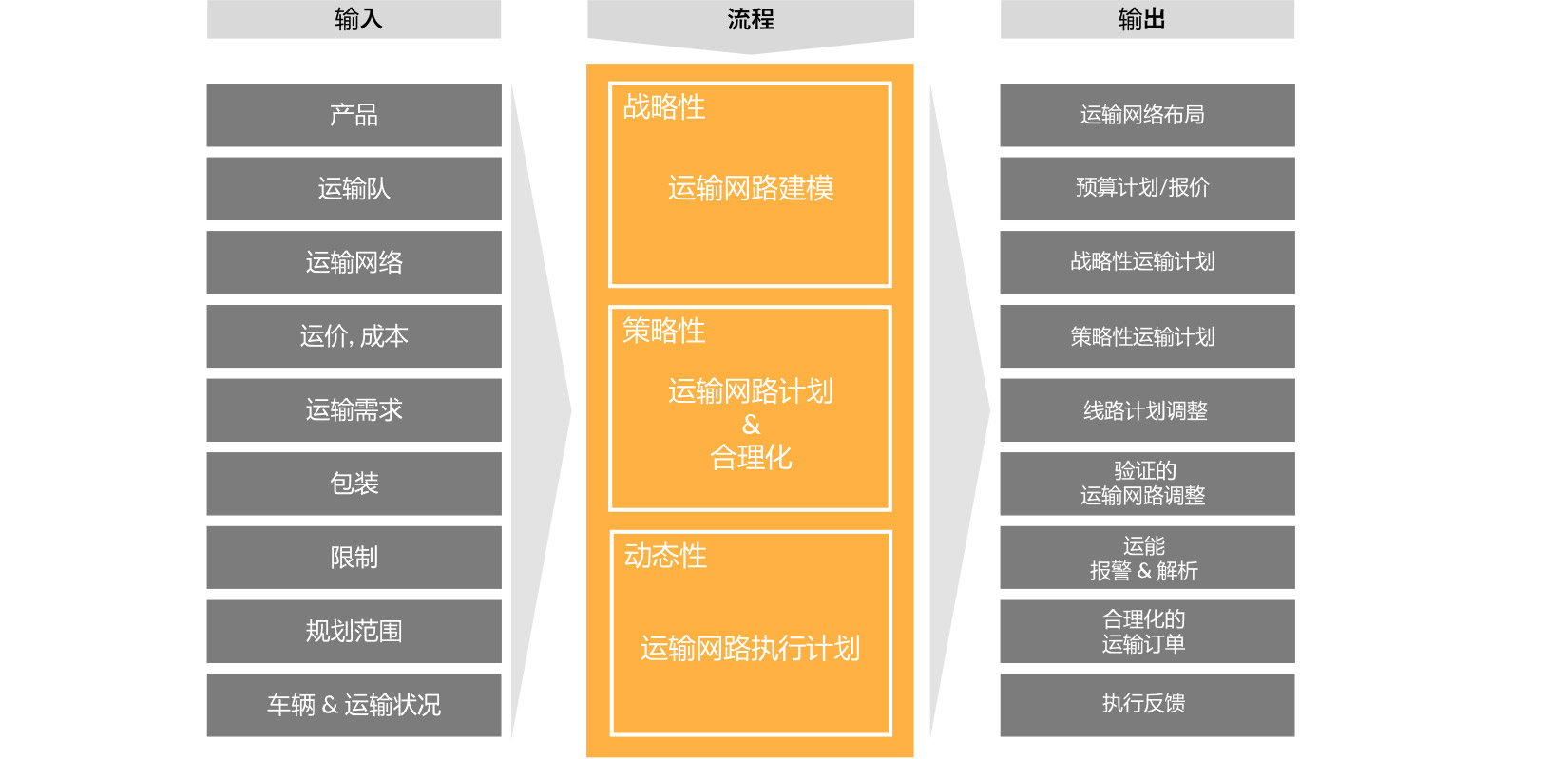

通过flexis SCM的运输计划与调度解决方案,调度员和计划员可以设计和优化运输方案。该方案可以根据动态的运输需求,对运输网络、线路和频次进行综合规划。

结果

通过更迅速的和网络化的计划,调度流程变得更加可靠和经济。基于系统的自动化和持续改善确保了供应链管理和运输计划的更高效率。

效应

运输计划与调度是一个全天候支持的解决方案,可以模块化使用。这个重要的规划工具支持优化路线规划,并为调度计划人员提供整体化的概况。该系统不仅显示了备选的实施方案,而且从物流和运输的角度显示了其成本视角。这样一来,实现快速投资回报率。

详细描述

flexis运输计划方案基于可持续检索的数据,实现了与所有相关方的协调。这使得调度员可以计划和安排整个网络和车辆的路径。该方案可以实现模拟,并提供场景方案管理,以便最终找到最有效的运输方案。通过分析、数据整合和地理位置服务,可以进行实时预测。在数字供应链数字双胞胎中,计划人员可以测试各种方案,并根据这些方案做出最优决策。这使得入站和出站的运输计划得到优化,并在整个供应链上进行整合。

We partner with:

-

为实现便捷和用户界面友好的路线优化功能,我们将我们合作伙伴HERE公司的定位数据库集成到我们的解决方案中。

-

我们很荣幸与我们的合作伙伴project44合作,后者是实时交通可视性的领先提供商。 数据的支配和使用以最大程度地提高供应链的可视化,然后通过flexis运输计划和调度解决方案对其进行优化,从而确保供应链的最大灵活性。

增值

- 统一的运输和需求规划:在供应链管理中,以端对端方案取消孤立思维,从而实现集成的规划和执行的一体化。提高运输费用和内部物流费用均衡。如果需要,在规划兼顾到绿色环保目标,促进整个供应链的端对端决策。

- 决策的性能和速度:允许自动的、快捷的决策,并行处理代替先后处理。消除了信息流之间的延迟:需求与交付、运输与成本结构。实现组织内部的信息和决策的实时交流。

- 更精确的决策:优化准确的决策,容易与一系列终极目标和限制条件相结合。通过整合分析,为供应链提供新的更好的算法。支持在不稳定的供应链中进行精细、高频、主动的决策。

- 更大的弹性:支持智能可靠的供应链管理,使供应链在成本和服务方面具有弹性。改善供应链的风险管理。实现实时重新计划。包括自动适应和实时分析。提供密集的数据质量。

flexis 解决方案一览

实情

减少规划工作量

直至

60%

减少运输成本

直至

20%

降低二氧化碳排放量

直至

15%