APS - Detailed Scheduling

flexis Detailed Scheduling optimizes production programs and creates transparency for demand, resources and capacities. This gives the production planner precise information to provide to the customer. The standard software with interfaces to MES and ERP can be used without software installation and can be operated in the cloud. A fast, simple, and scalable implementation across the company powers immediate, transparent evaluations of the processes.

Outcome

Costs are reduced through reduced setup efforts, minimal idle times and improved process flows.

Benefit

The professional, user-friendly standard software from the automotive complex is adapted for medium-sized companies. Messages can be integrated into the system via MES/BDE interfaces or manual entry.

Detailed Description

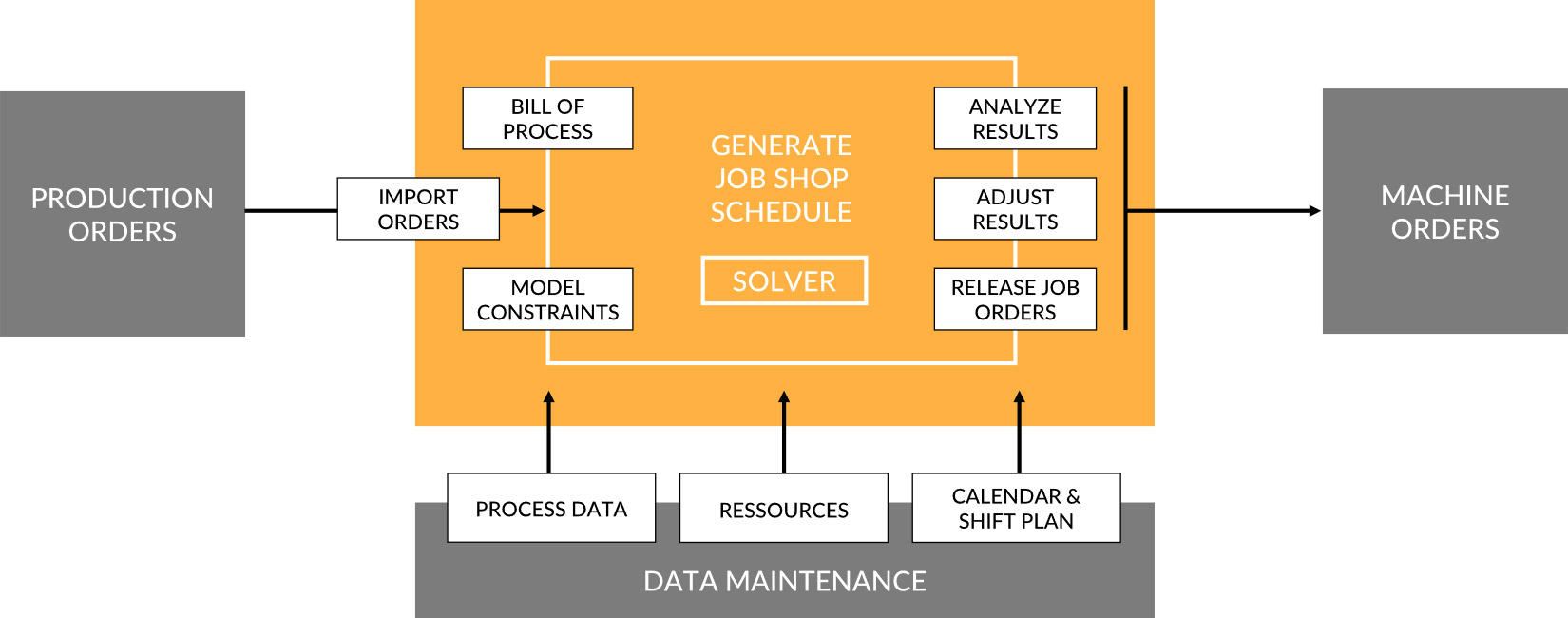

flexis Detailed Scheduling compares planning values and actual feedback for well-founded replanning. Schedule changes can be adjusted by drag & drop, reducing manual effort (e.g. using Excel tables). The program provides a decision-making aid in the event of conflicting objectives and gives an overview of work content, machine occupancy, processing times, staff and parts requirements and resource utilization. Customer communication is improved by the creation of what-if scenarios.

Added Value

- The digital twin check creates different scenarios and thus provides precise information to sales and customers

- Cost savings through optimization of process flows and thus minimization of set-up work and idle times

- Higher efficiency in production planning and logistics

- Higher productivity

- Know-how is structured and archived

- Cloud solution without hardware investment or software installation

flexis solution overview